MFH-5320-B Premium Mercruiser V6-V8 Block & Manifold Dry Joint Kit

SKU: MRCMFH-5320-B

MFH-5320-B Premium Mercruiser V6-V8 Block & Manifold Dry Joint Kit

CONVERSION KIT FITS

The MFH-5320-B works with 383 engines that have the 5” pulley on the jacket water circulating pump. 383 engines with the 6” pulley need these additional parts to change out the pulley for the 5” that are not included in the kit. • Belt 1 x 865615Q06 (sterndrive) or Belt 1 x 865615Q10 (inboard) • Elbow/Fitting 1 x 860346 • Hose 1 x 864551 • Pulley 1 x 865047T This increases the flow through the engine and heat exchanger so the over-temperature alarm will not sound after running at high RPM then returning to idle. 2002- present MerCruiser GM 4.3L, 5.0L and 5.7L (262, 305 and 350 CID) model with a single serpentine belt/single-belt (will NOT fit v-belt or multi-belt equipped engines) Sterndrive and inboard (EXCEPT V-drive installations). For sterndrive applications, the power steering pump should be mounted low on the port side and alternator on the upper starboard side (For engines with the power steering mounted high on the port side and serpentine belt order kit MFH-5230). For inboard applications, the alternator should be located on the lower starboard side of the engine.

SPACE REQUIREMENTS

Heat exchanger is 4-1/8" diameter x 23-1/2" long and fits within overall length, width, and height of most engine conversions (adds 1-1/2" to overall length of 2001 and newer MPI installations). Heat exchanger extends from extreme starboard side of a normal exhaust manifold towards port side (see Figures 1-4). Plastic expansion tank mounts either on front of heat exchanger or if space is limited on vertical surface next to engine.

APPLICATION NOTES

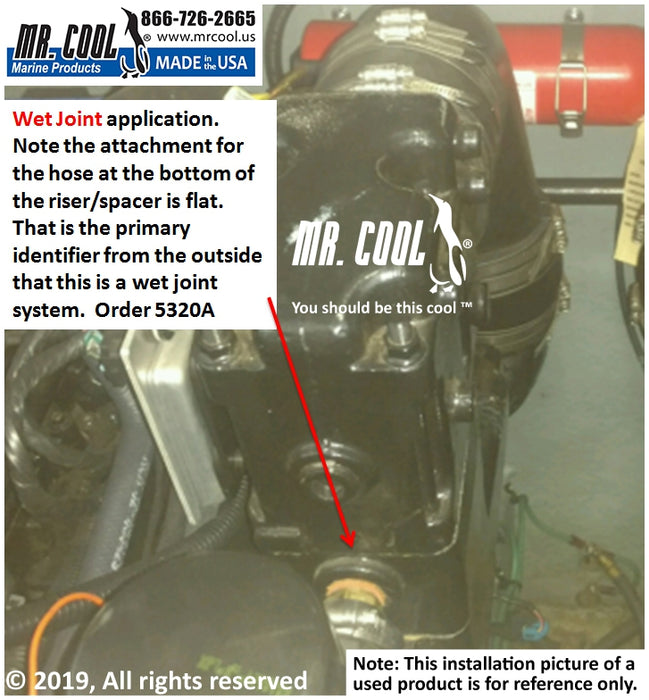

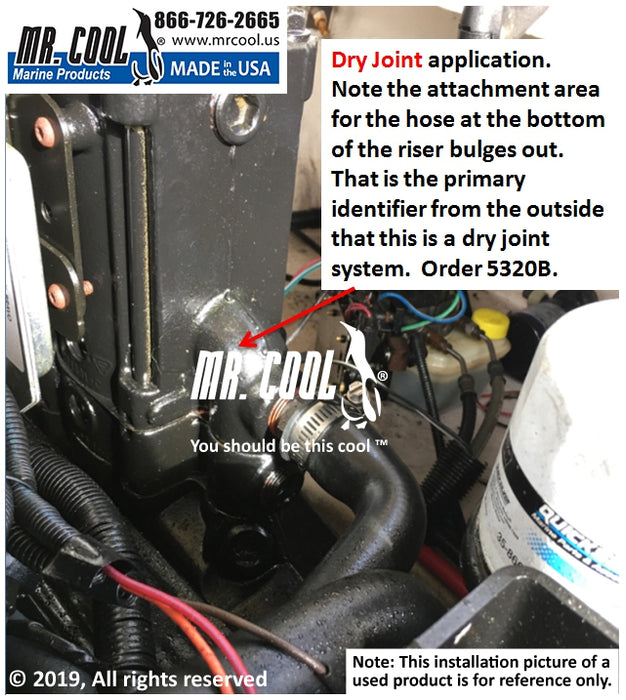

We supply two kits, depending on the design of the exhaust system. 2002 or newer V8 applications (serial #0M600000 & Above) and 2003 or newer V6 applications (serial #0M615000 & Above) were equipped with an exhaust system termed "Dry Joint". Order FWC Conversion kit # MFH-5320-B. This kit includes: two Dry Joint block-off gaskets, a lube oil bracket, a strap, and two fasteners. The Dry Joint gaskets are used on Dry Joint applications only and the lube oil bracket is required to relocate lube oil bottle that is mounted to the inside of the lift eye/power steering bracket (serial#0M640000 & Above) Older engines with the Non-Dry Joint require FWC Conversion kit # MFH-5320-A. This kit includes two standard block-off gaskets.

COOLING SYSTEM TYPE

This kit is a "full" fresh water cooling [FWC] system; meaning that the engine block and exhaust manifolds are protected by the system. Exhaust elbows remain on the raw water system. System utilizes a unique, high performance heat exchanger with built-in full flow thermostat bypass control ensuring optimal jacket and exhaust manifold water flow and consistent temperature under all operating conditions. Our FWC systems are specially designed for the low capacity raw water pumps used on sterndrive engines.

CONVERSION KIT KIT INCLUDES

heat exchanger, heavy-duty translucent plastic expansion tank, complete instructions all other components necessary to convert a raw water cooled engine to FWC. Some existing water hoses and hose clamps are reused. Heat exchanger, thermostat housing and mounting brackets are finished in black. Fasteners are zinc/cadmium plated or stainless steel. All hose clamps are 3XX series stainless steel.

HEAT EXCHANGER

High-flow, shell and tube design allowing a higher cooling capacity than standard. All copper alloy construction made to the highest industry standards. Includes heavy-duty, dual, demountable end covers for easy clean-out. COOLING SYSTEM CAPACITY Will maintain coolant temperatures in the 160-170 degree F range using 160degree F thermostat included in kit. System has cooling capacity safety margin higher than industry standards.

HEATER SYSTEM HOOKUP

Heaters such as galley water heaters and cabin heaters are easily supplied by utilizing the 3/8" NPT fitting on top of the lower heat exchanger bracket for the inlet. The outlet to the heater should be connected to a fitting on the engine circulating pump (normally a NPT thread).

INSTALLATION TIME

Average installation time is approximately four hours, assuming new engine and normal accessibility. Allow additional time for filling and testing. Installation skills are typical of most do-it-yourself boat owners. Complete illustrated installation instructions are included in kit.

WARRANTY Two year warranty.